|

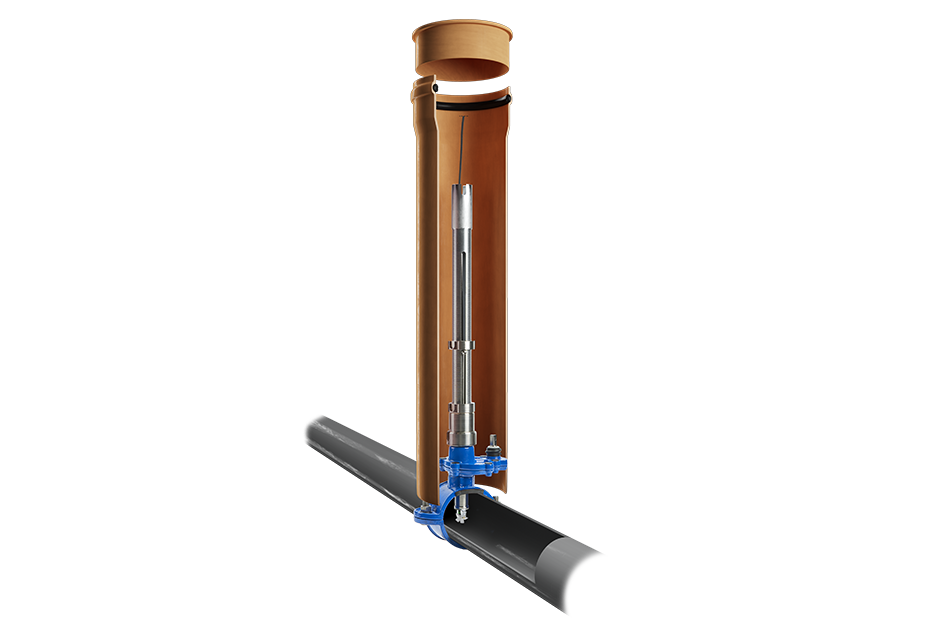

AQ IoT Insertable Flowmeter for small manholes, hybrid technologyFrom DN 80/500Minimum flow rate 0.019 m/s For plastic, metal and concrete pipes Installation space, minimum length 160 mm Measurements in both directions Battery powered via AQ Logger (over 6 years) Insertable under pressure Installation in less than 4 hours Pressure and temperature sensor option Connector for easy connection to the device The AQ FLOW SENSOR Insertable Flow Meter for small manholes is an in-house innovation and patented technology. The advantage of the device is the ease of installation without closing the pipeline and the integration into existing infrastructure (hot tapping). The AQ IoT Flow Sensor can be installed on all types of pipes. The installation itself is done by digging a hole to the pipe and fitting the coupling to the pipeline. The AQ IoT Flow Sensor for small manholes is installed in the coupling and the DN 400 pipe used for the manhole casing is installed on the coupling. Backfill the pipe with the casing to create a manhole for the AQ IoT Flow sensor that can always be accessed with a special tool, even if the Flow sensor is more than 2.5 metres deep. The pipe used for the shaft is closed with a road cap. In less than 4 hours the pipeline provides accurate flow, pressure and temperature data. The device consists of an electronic circuit that counts the rotation - direction and speed of the propeller. With a chip on the electronic circuit, the rotation of the propeller can be monitored precisely and we always know the exact position of the propeller. This allows us to have extreme precision and low minimum flows. Each device is tested on an accredited measuring line (SIST EN 17020) with seven-point calibration, providing extremely good measurements and low minimum flows. When installed correctly (15 x DN at the front and 5 x at the rear), the accuracy is below 3% with a minimum flow below 0.019 m/s. The design of the propeller and the height in the pipe itself also make the device suitable for pipelines with a higher percentage of solid particles in the pipeline. Sustainability values were key in the design as the device can always be serviced. The product has an expected service life of 5 years (depending on water quality) and can be serviced and recalibrated in the event of wear or damage. The hybrid technology allows real-time measurements, which is not possible with MID or ultrasonic technology. This means that with our measurement system every revolution counts, not just interval measurements every 15 minutes. In case we do not have the possibility to work straight in front of and behind the device, our measurements will not be within tolerances, but we will still be informed about the trend of what is happening in the pipeline as well as silent spills or burst pipes. The meter is bundled with the AQ IoT Meter Logger which powers the meter and the communication device via batteries, and runs for over 6 years when set up correctly. Communication 2G/3G/4G (SMS) NB-IoT (SMS) LoRaWan WiFi Device data Input 1,2 forward, reverse flow Input 3,4 pressure and temperature Battery status Communication signal status Internal power consumption Temperature and humidity inside the device Valve open or closed (ON/OFF switch) Date and time (synchronised on each transmission) Communication protocol AQ Protocol MQTT |